Lab Grown Diamond Jewellery Manufacturing Process

Grow Rough Diamond

A rough CVD diamond is grown from a diamond plate. Like real diamonds the seed is put in lab environment that contains gases and right temperature conditions to develop carbon formations into rough diamonds. These conditions are similar to one found under Earth’s crust. To know whole process

Scrutinize and Select Rough Diamond

After the rough diamond is grown each rough diamond is carefully scrutinized by physicists and experts where inclusions are noted and the yield of the rough is determined and based on its yield expert’s carefully select rough diamonds that has right clarity characteristics and minimal inclusions.

Scanning & Planning

The selected rough diamond is passed through 3D scanner and planners plan with the best shape and size possibilities with it.

Stone Marking

Once the plan is final our diamond marker mark diamonds on both side depending on the characteristics and inclusions present in the diamond. It is then forwarded to Laser Sawing Department.

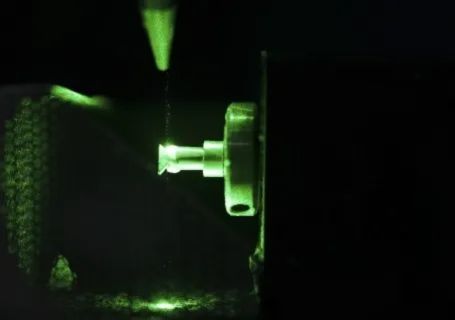

Laser Process

Each marked rough diamond is individually set on brass dopstick to secure its place. Diamond cutter carefully matches diamond position and grooves and then through laser process the rough diamond is sliced into separate pieces.

Plan Verification

The rough diamond piece is again sent to Planning Department to re verify with plan and amendments are made if any and sent for final cutting process.

Final Laser Process

The final shape is then cut with advanced laser processing systems to derive right shape and cuts.

HPHT Process

The diamond is then sent for HPHT process to improve its fluorescence. Nearly all diamonds have some degree of brown or yellow color. With HPHT its color is improved.

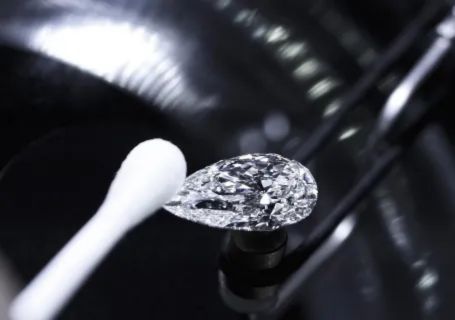

Polishing

Then our proficient diamond cutter and polisher polish the facets and shape to refract and reflect the optimal amount of shine and scintillation and to obtain ideal proportions and perfect symmetry.

Internal Grading

Then our in house diamond graders who an eye to access and determine the quality of the diamond grades the diamond.

Boiling & Cleaning

Lastly the polished diamond is kept in chemical for 24 hours to remove all the impurities, dust particles, lint and or hand or finger prints.

Certification

Lastly Diamond is then sent for certification. The International Gemological Institute (IGI) is world’s largest independent laboratory that carefully studies lab grown diamonds for its authenticity. It assesses a diamond’s cut, color, clarity and carat weight.